Friday I picked up Eave Caps for My Vardo Roof and Saturday we worked on Plan F. Yesterday we worked on Plan F: Take 2. And today we (finally!) insulated my roof box!

Friday I picked up Eave Caps for My Vardo Roof and Saturday we worked on Plan F. Yesterday we worked on Plan F: Take 2. And today we (finally!) insulated my roof box!

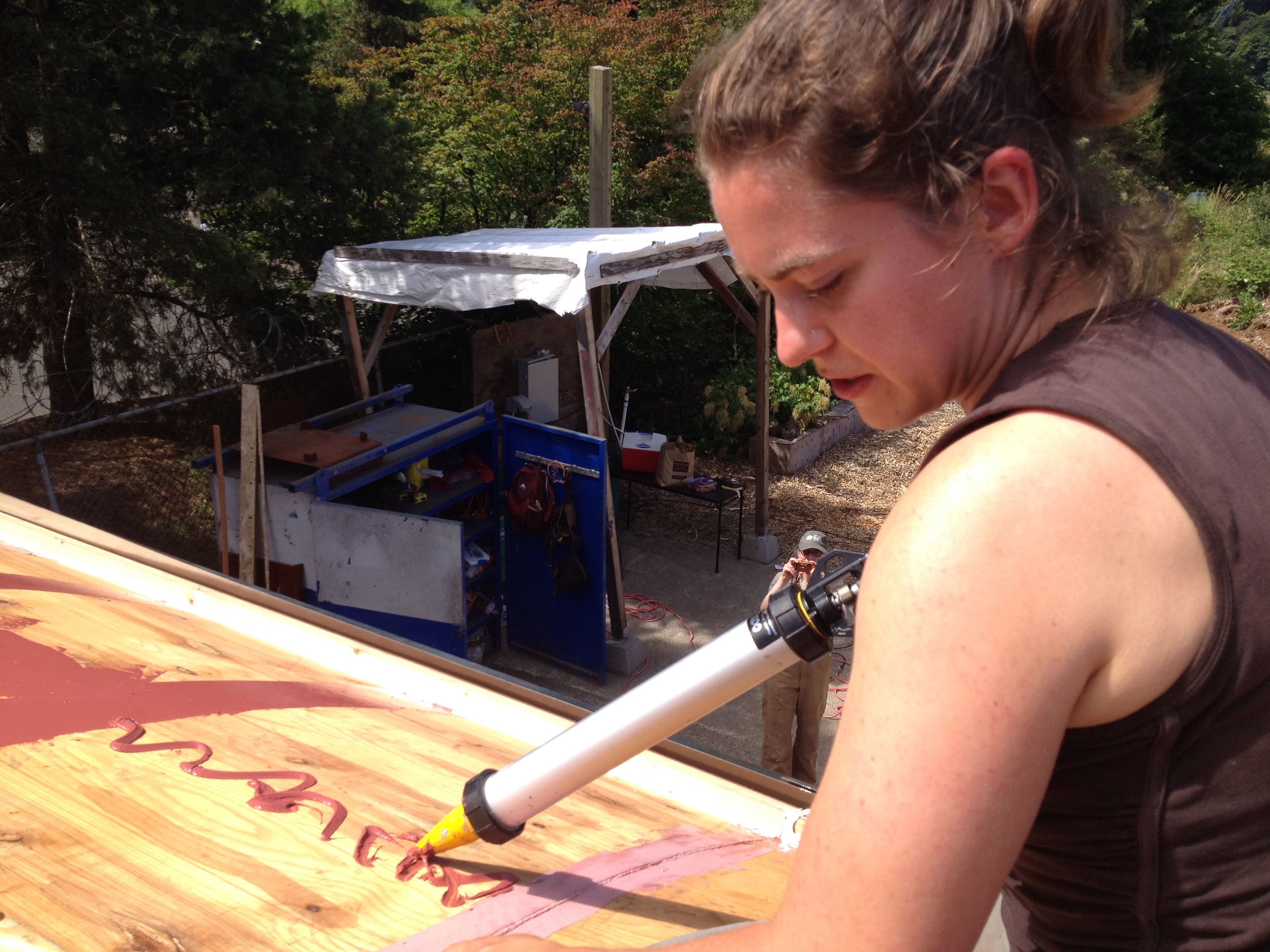

In the morning Matthew helped me air seal the ceiling. This involved running Fast Flash from the R-Guard system by Prosoco over all of the seams where we’d nailed the ceiling bead board. (You can read about my bead board ceiling in Ceiling Up My Vardo.) Matthew also helped me find the weak points in the ceiling panels by standing inside the house and looking for the spots where the ceiling was translucent. I was on the roof so I tested to see if I had the right spot by covering up the area with my hand. If I blocked the light I knew I’d found my target. (Though I had to remember to not block the area with my shadow since it was so sunny!) I covered these areas with Fast Flash, too. Once the roof was no longer see-through we were ready for the insulation.

This afternoon Tony and Grae helped me install the insulation in my vardo roofbox. We cut 4’ x 8’ sheets of 1” expanded polystyrene (EPS) foam board to fit between the 2x6 at the eves and the outriggers surrounding the skylight box. We decided to leave the spots on either end of the skylight box at the front and back of the house till last because it’s such a nice place to sit and store tools without them slipping off the roof!

Once we’d dry-fitted the foam we removed it and spray foamed the edges. Then slipped the sheets of insulation into place. Once the first piece was in place we put in another 1” sheet of EPS on top of it. Fortunately, these sheets didn’t need to be cut, just tacked down onto the nailers and spray foamed at the edges. As we installed the insulation we discovered we’d installed the skylight box slightly askew, so we cut a couple long strips to fill in the gap. We’ll need to do the same for the sheathing.

My walls have 3 ½ of EPS insulation in the SIPS and my floors have 5 ½” of XPS (extruded polystyrene) insulation because I hate having cold feet. Ideally I would have had at least as much insulation in my roof as in my walls. So I ordered the Eve Caps for My Vardo Roof to be 3 ½” tall – 3” for foam and ½” for the sheathing. Unfortunately, I didn’t account for the losses created by the angles. So once we got the second piece of 1” foam into the roof we realized we wouldn’t be able to get more than 2” of foam inside the eve caps with the sheathing in there, too. (The fellow at Vinje’s mentioned when I picked up the Eave Caps for My Vardo Roof that he’d read my blog and he wasn’t sure I’d be able to get 3” of insulation in there. Glad he thought of it, but I wish I’d talked it through with him sooner!)

I am bummed that my roof isn’t better insulated, but as my fellow tiny house builders/energy auditors remind me, my decision to put skylights right in the top of my house pretty much negates the insulation I put in the roof. So I don’t have the best insulation to prevent conductive heat transfer. I’m going to count on that air sealing to help with convective heat transfer. My New Custom Skylight (which will replace the one I broke on my day of Hail and High Water) will help with radiant heat transfer.

I was hoping to get the sheathing up today, too, but the breeze tends to pick up in the evenings on our site and it seemed precarious for Grae and I to be lugging sheets of plywood up ladders, only to have the caught by the wind. Besides, I, for one, was getting pretty tired by this point. It was hot today! But it's expected to rain over the next couple days, so we decided to tarp the house up (again! But hopefully for the last time!)

As evening approached I took a break to get milkshakes for me and my build buddy Laura and then helped her with her siding a little bit before calling it a day. You can read more about Laura’s siding on and A Little Bit of Everything else on her blog.