This post is an excerpt from an epic post from Kate Goodnight's blog about the first two weeks of construction for Naj Haus. If you want to read the full post Blood, sweat, tears, blueberries, and the most awesome three walls ever, you can find it on Kate's informative and amusing blog. Thank you so much Kate for the opportunity to be part of your tiny house raising!

July 5: Hitting the nonexistent wall

So here I was, the day before the barn raising, and I had no walls to raise despite my best intentions. I can’t remember when I was last that tired. I started having visions of the six participants looking around the empty barn. “What?” I’d say, “can’t you see the walls? They’re right there. Look harder. They are very fine walls and we’re going to raise them up.” I still had some deluded idea of getting one or two walls built that day so went weaving down the highway back to Home Depot where I just stood staring at complicated hardware and the empty rack of sheathing before returning nearly empty-handed. I was so tired I thought I was going to throw up. Dee’s other work party had just wrapped up so we talked about how to adapt things. We (I) scaled way back on our (my) expectations and decided to focus on wall framing and if we were really lucky, get one or two walls raised. Finally letting go of what I had envisioned, I got in an hour nap before Dee and Lina Menard, the other PAD instructor, arrived, followed later by Keeva and Sam. We spent the evening marking out the stud positions on the subfloor and crashed early.

The big day finally had arrived. I had gotten some sleep so was feeling a bit better. Now I had to wrestle with my control issues. I have been all-consumed for the last many months with the design and planning of this tiny house and I was going to have to now let go. Here were six complete strangers with varying degrees of building experience about to start chopping away on my studs and hopefully framing up something resembling squared walls. As I greeted each one I was wondering how steady their hands were, how keen their eyes. Would I soon be hearing muffled cries of “whoops…oh well” and see the bubble in the level crammed up in one corner as it rested on my new Dr. Seuss walls?

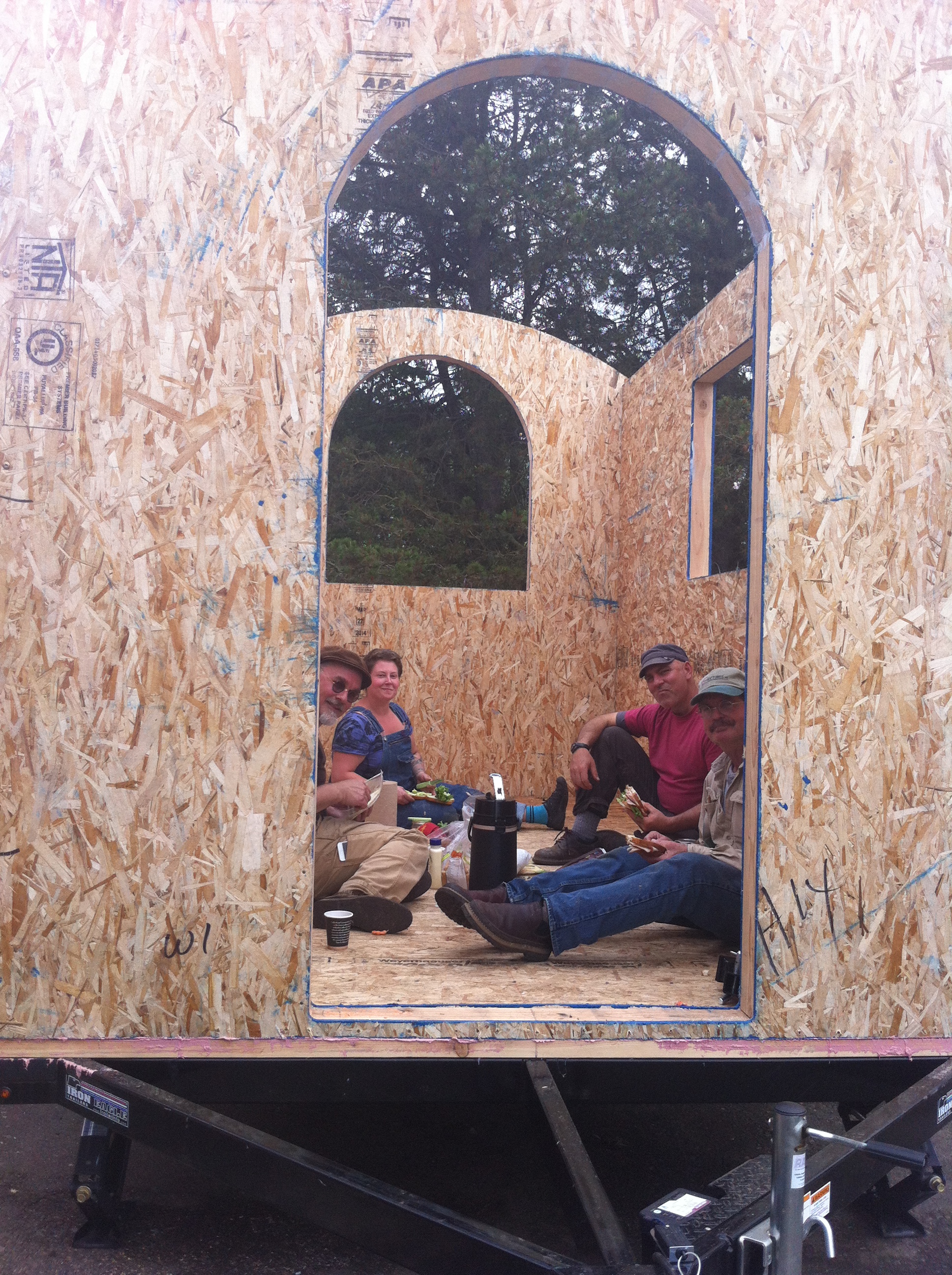

But you know what? Each and every one there took immense care as they assembled the walls, treating them as if they were their own. The more seasoned builders helped out the less experienced ones and all were carefully overseen by Dee and Lina, both amazing instructors. Within the first hour, I had ceased to worry. In fact it was a relief to turn over the reins for a while and know that it was all being done up right.

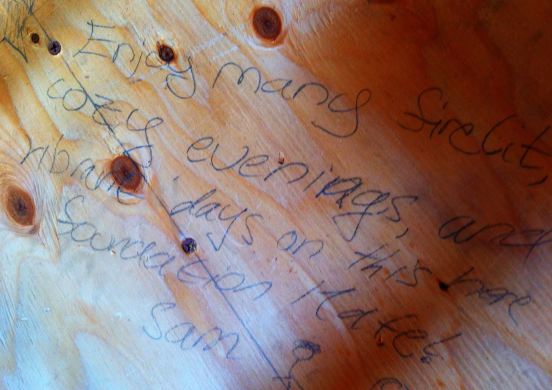

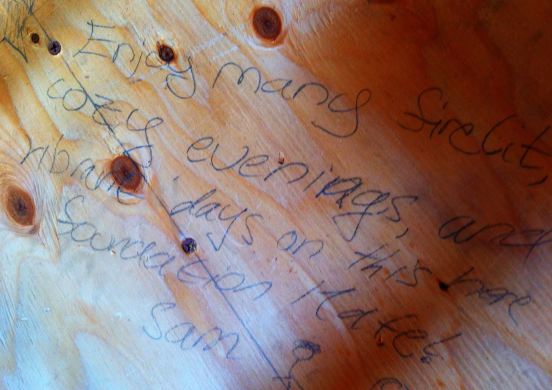

And we had fun. We did the teacup stretch and ran crazily around the tiny house, then around the outside of the barn, snagging blueberries along the way. When we went to raise the long second wall, Sam G. put on the Ride of the Valkyries and the wall was lifted in place with great operatic flourish. To my utter astonishment, the rockstar team was able to get a third wall built. When it was raised in place, it initially looked like it wouldn’t fit under the top plate of the second wall. Sam G. climbed up on a ladder and gave it a couple good thumps with a hammer and it slid into place like an arm into its socket. What’s more it was perfectly square and plumb, which almost never happens. I was now feeling pretty sheepish about having doubted this wonderful crew. They are a bunch of beautiful, good-hearted human beings, setting off on their own tiny house journeys. Several talked about how empowered they now feel. I love that their energy is part of my house and hope that I can return the favor in some way.

On June 13-14 I'll be teaching a two-day Tiny House SIPs Wall Raising Workshop in Portland, OR in conjunction with Patrick Sughrue of Artisan Tiny House. Two weekends later we'll do a Tiny House Exterior Trim & Siding Workshop to install windows, rain screen, trim, and siding. Space is limited, so if you're interested in building this summer (and especially if you're interested in building with SIPs), claim your spot today!

On June 13-14 I'll be teaching a two-day Tiny House SIPs Wall Raising Workshop in Portland, OR in conjunction with Patrick Sughrue of Artisan Tiny House. Two weekends later we'll do a Tiny House Exterior Trim & Siding Workshop to install windows, rain screen, trim, and siding. Space is limited, so if you're interested in building this summer (and especially if you're interested in building with SIPs), claim your spot today!